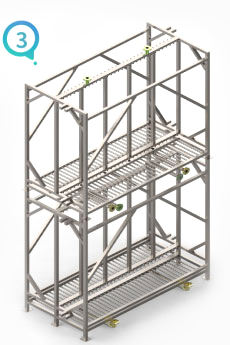

- Space-saving; engrgy-saving

- Customization for more choice

- Easy for cleaning and maintenance

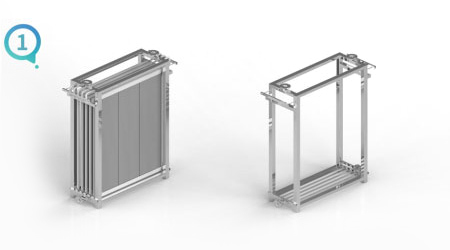

Integrated skids of modules can be supplied based on customers’ requirements

The container plants is made of carbon steel, and the service life can be up to more than 20 years.

MBR Integrated Equipment is able to undergo flexible configuration based on quality of raw water,ensuring wide application of the equipment.

Food beverage industry

Municipal wastewater reuse

Chemical printing dyeing industry

Electronic plating industry

Mining Production Industry

Power metallurgy industry

Pharmaceutical Industry

Municipal water supply and desalination

We will gladly place the requested document at your disposal. Kindly fill in the following form. You will Download the document immediately.

* Required fields