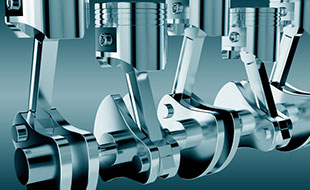

1. From 2009 to 2015, RELIABLE was an OEM team for EUROPEAN and AERICAN machines; years of OEM experience made RELIABLE controlled the core technology on high quality, high safety machine manufacturing, thus made our advantage on leading technology.

2. From OEM to independent brand business, RELIABLE deeply realized the importance of the team for a brand; the RELIABLE team is composed of experienced staff, whose average experience more than 10 years in this filed; and all of departments keep timely and friendly communication for customers suggestions, discuss the improvement of design and installation.

3. We control the quality not only check each single piece of spare part, but also simulate machine’s actual working to check each spare part’s fit precision during our installation, ensure our machines’ best precision; thanks to the cooperation with the SGS, CE and ISO, ensure our machines’ reliability.

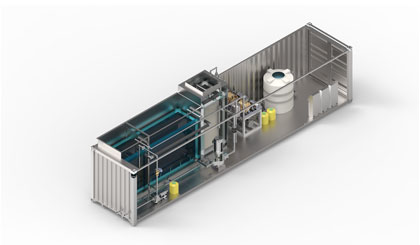

4. With the increasing demands of plastic quality and quantity, injection molding factories required machines higher and higher, RELIABLE keeps the developmental innovation and research on precision, efficiency, safety and special material injection molding.